by Neal Pillsbury 1998 U270 36′ 12/28/10

I had a different problem that was easily resolved. It may be of some use to you or others. My U270 (as-built, ’98) had no air chuck. In looking at the air system design, I felt that adding an air chuck directly to the Bendix D2 governor valve body made the most sense.

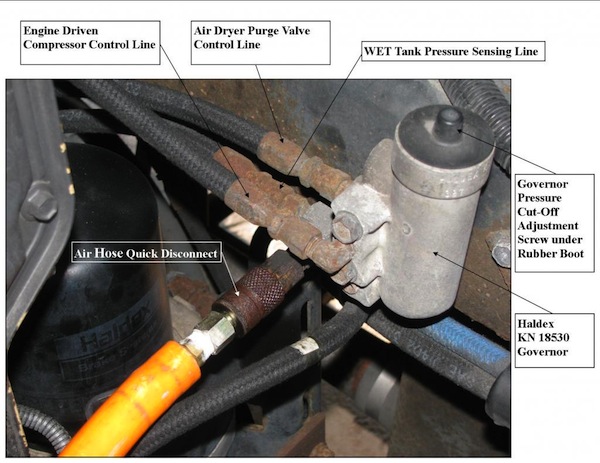

As you can see, the (3) Bendix D2 Governor “reservoir ports” are common within the Governor valve body. On my coach, two ports had 1/8″PT plugs and the third references (is connected to) the first (WET) air system tank. Thus, by removing one of the “reservoir port” plugs and adding a quick disconnect air hose fitting there, I would be tapping into the first air tank (highest) pressure, and if I caused any appreciable airflow pressure drops in airing up my tires, I would be doing it right at the very best place to cause the governor valve to shift, causing the compressor to start sending makeup air to the wet tank. Thus “droop” in the system would be minimal before the governor shifted. And, if the governor didn’t shift, all I had to do was manually vent the air chuck for a couple of seconds and the governor would shift as it sensed the lowered pressure.

That helps a great deal in that I don’t have to keep hopping in and out of the coach to use the braking system to lower air system pressure (or rely upon a helper) to shift the Governor, to get back to the higher pressures in the air system.

I keep a rubber plug in the Governor-installed, quick disconnect air fitting, to keep dust and particles out, when not using an air hose.

Also, installing a Schroeder valve in the other plugged Bendix D2 “reservoir port”, would give you a way to check your WET tank air pressure. Or, as I have done, using the KISS principle (to keep maintenance down and reliability up), just install a Schroeder valve in your air hose. In a static system, air pressure at the far end of your air hose is exactly equal to your WET tank internal pressure.

Quick disconnect air fittings are pretty reliable and meant to take a lot of everyday abuse. A quick-disconnect fitting seal is designed to avoid damage as you connect and disconnect from it and when disconnected, system air pressure only improves the seating force. I just keep mine covered with a film of Corrosion-X and have had no leaks since installation more than 10 years and 145K(+) miles ago.

More costly quick disconnect fittings generally improve the ball detents (or line contact detents) and internal springs with ultimate corrosion-resistant materials, but that just aids in helping a connected air hose to stay connected under abusive strain conditions, not in the strength of the fitting itself. Following the KISS principle, I’d keep the complexity down and trust an already rugged and highly reliable quick disconnect fitting, complimented with a little Corrosion-X once in a while. Adding a valve and more fittings just raise the probability of some other problem occurring.

The air hose is just inexpensive, industrial grade, air hose — 3/8in. x 40ft., 250 PSI, I think. Any Lowes, Home Depot, Northern Hydraulic, etc. would have it, and usually, you can find it for $20 or less.

It has worked great for me for 10(+) years.

Also of my air hose that has been very cost-effective (it was a gift).