I was recently privileged to attend the Life on Wheels Conference as an instructor. My classes were primarily designed to instruct newbies in the safe and friendly use of their new recreational vehicles. I shared these responsibilities with Steve Savage, another Master Certified technician, who has his own mobile RV service in Bristol, TN. In the classroom setting, it fell to me to do an impromptu lecture on propane. The RV industry as a whole has chosen to discontinue the use of “LPG” to describe what is commonly used in the heater, water heater, etc. It is now referred to as propane or propane vapor. While doing this presentation I realized I have never done one of these articles on propane. Propane is very important in a recreational vehicle.

A few facts about propane:

1. Propane has ethyl mercaptan added to produce a rotten egg, garlic smell.

2. Propane is flammable at 2.15% to 9.6% propane to air ratio. Less and there is not enough propane vapor, more and there is not enough oxygen.

3. Propane weighs 4.2 pounds per gallon of liquid.

4. Low temperature and low amounts of propane in a container can diminish the efficiency of a propane system. Possibly to the point, the appliance may not work properly.

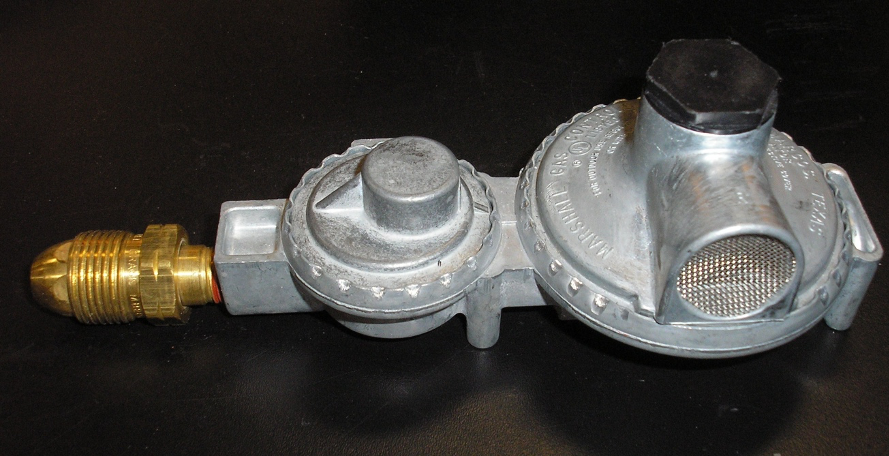

An example of a propane regulator.

The heart of any propane system is the regulator. Two-stage regulators are used on today’s RVs. The first stage cuts container pressure to 10PSI while the second stage cuts the pressure to 11 water column inches nominal (6.36 ounces). This is the pressure that should be delivered to your RV appliances for the best operation. Many appliances have an additional regulator that cuts the pressure down to 10 water column inches. This tends to smooth out the pressure and allow the appliances to operate at peak efficiency.

There are three checks you should have done annually to your regulator. These checks are often considered not important. I consider them very important. One is called a lock-up test which is where your regulator is checked to be certain that under no circumstances it allows more than 14WCI to enter your propane distribution system. This check should be done annually as a safety factor. The second check is an operating pressure system check, a check to ensure that the regulator is holding the proper pressure when many of the propane appliances are burning. When your regulator passes these operational tests, your propane system is operating at peak efficiency. There still may be a leak. The third test is a timed drop pressure test.

Another extremely important test that must be done annually is a timed drop pressure test. This is a test that is done at 8WCI for a period of no less than three minutes. This test is to LOOK FOR THE EXISTENCE OF A LEAK IN YOUR PROPANE SYSTEM. This test will not find the leak. It will simply verify the existence or non-existence of a leak. This test should be done at least on an annual basis or any time a propane leak is suspected. It should also be done anytime the propane system is violated. The word violates means the propane system is opened, unhooked or changed. This is obviously a major safety issue and should be done by a qualified, trained technician using properly calibrated equipment in good condition. The instrument used for all three propane checks is called a manometer, as shown at the left.

An open flame should never be used to search for a propane leak. The two most commonly accepted methods to find a leak are an electronic leak detector and a liquid leak detector. The only acceptable liquid leak detector is commercially made for this purpose. Soap and water should never be used to look for a leak. The soap and water residue can damage the fittings. If you see green around a brass fitting soap and water has been used. Long term this can cause a leak. Only a propane leak detector formulated for this purpose should be used.

A covered regulator.

Regulators should always be covered or in a compartment that restricts water from getting in. This is an oversimplification of the RVIA code. A towable with a cover over all of the propane storage systems including the regulator is considered to be covered. Motorhomes with an underbelly tank need to have a cover over the regulator. Regulators have a vent that allows them to breathe as the diaphragm moves up and down to control the pressure. This vent should always point within 45° of straight down. There are two reasons for this, to restrict water from entering and if it does enter allow it to get out.

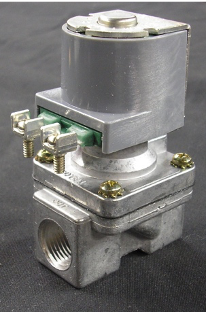

Propane detectors (an example is on the right) have been required for RVs for the past several years. If your propane detector puts out a beep-beep sound this generally indicates a low battery in your RV. If your propane detector goes off with a solid sound this would generally indicate a propane leak. Propane detectors will sometimes alert with such things as cleaning solvents, any type of aerosol spray can be used, new coach odors, fuel vapors, adhesives, etc. Human and animal intestinal gases can also set off a propane detector. Some propane detectors on motorized RVs have a solenoid valve that will automatically shut off the propane supply when the propane detector alarms. You can reset and open this solenoid valve by turning off the propane detector switch, waiting one minute and then turning it back on. If there is truly a propane leak the detector will alarm and/or not open the solenoid valve. Anytime the propane detector alarms take proper safety precautions. Propane detectors have a limited life span. Most manufacturers recommend they be replaced after about seven years. Read the owner’s manual for specifics.

TOWABLE PROPANE SYSTEMS: Towables use propane cylinders to store the propane. Two 30 lb. cylinders with an automatic changeover regulator are most common. Some fold downs and smaller towables have two 20 lb. cylinders with or without an automatic changeover regulator. An automatic changeover regulator is simply a device that when one cylinder runs out of vapor the reserve cylinder begins supplying the vapor, both cylinder service valves must be open. A red flag appears on the top of the regulator when one of the cylinders is empty. The arrow or lever will be pointing toward the empty cylinder when this happens. Turn the arrow towards the other cylinder and a green flag should appear. Close the empty cylinder valve and take it to be refilled. Reinstall the full cylinder, reopen the valve and it will be ready to take over when the cylinder supplying the system becomes empty.

Since April 2002 all cylinders have been required to have an overfill prevention device (OPD). When this safety device is operating properly it is impossible to overfill the cylinder. It is possible to install an OPD in an older cylinder. However, the bottle must be recertified. All propane cylinders must be recertified by law after 12 years and every 5 years thereafter. It is illegal to fill a cylinder that does not have current certification and an OPD fill valve. A horizontal cylinder is not required to have an OPD valve. Record your required recertification date and have it recertified as required by law. This can also be a safety issue. The date of certification will be stamped on the collar of the cylinder when it is made and when it is recertified. The empty cylinder weight (Tare Weight) and water capacity in pounds is also stamped (WC) on the collar.

The old left-handed, wrench type, connections have been replaced with a very user-friendly, hand tightened, right-handed, big green plastic nut that threads right on to the end of the new valves. The big green nut is on the end of a flexible hose called a “pigtail.” The pigtail connects to the RV’s propane regulator.

Let’s talk about a couple of safety features on these new pigtails. Both features are parts of the big green nut.

The first is a black thermal-sensitive bushing found just behind the green nut. If this bushing is ever in a fire with temperatures between 240°F and 300°F, it melts and allows the brass nipple inside the nut to move back about ¼ inch, which closes a small piston inside the cylinder valve totally shutting off the flow of propane. This innovative feature will help prevent fires or explosions.

The second new safety feature is called a “flow-limiting-device.” Its purpose is to restrict the flow of escaping gas if there is an excessive leak in the RV propane system. This second “flow-limiting-device” feature and how it works forms the core of the secret! Almost every time the cylinder valve is opened, a small ball in the center of the brass nipple (inside the green nut) is pushed forward into a brass seat. This seat doesn’t totally shut off the gas. By design, it allows a small amount of gas (by-pass flow) to go into the RV propane system. If everything in the propane system is closed and in the off position and there are no leaks, the by-pass flow builds up backpressure. This equalizes the pressure in the ball back of the seat and allows unrestricted flow through the system. All this happens in about five seconds and the user doesn’t know it’s happening, appliances light, furnaces and water heaters run as normal.

Now let’s look at the same system but with the oven control left in the pilot on position. Again the cylinder valve is opened, the ball is pushed into the seat, the by-pass flow goes through the system but this time it can’t equalize because the flow continues out through the open oven pilot. The user goes inside and starts cooking dinner. Two burners on the range top are lit and everything seems okay until the furnace comes on. At that point, the flames on the range top are drawn down and the furnace won’t ignite, everything seems starved out. The reason? We don’t have full-unrestricted cylinder flow to run our system, we only have the small by-pass flow which is far too small to feed the appliances trying to operate.

HOW TO FIX THE SITUATION: Turn off all the appliances, turn everything to the closed and off position, wait about 15 seconds. If the system is closed and tight, the backpressure builds up, equalizes and feeds unrestricted cylinder flow to the regulator for normal operation. If the system has a cracked fitting or split tube somewhere in the gas system the by-pass flow will not equalize until that leak is found and fixed.

Propane cylinders are generally found in pickup campers. Many older motorhomes also have them in a compartment off the side. From a safety standpoint, these compartments should be sealed from the inside living quarters of the RV. This is also true when a 5th Wheel has these cylinders mounted in a side compartment. RVIA code dictates the cylinders will be sealed from the inside living quarters.

Propane cylinders have what is known as a pressure relief. Anytime the container pressure exceeds 350PSI the pressure relief will begin releasing propane vapor. This generally happens in the case of a full propane cylinder setting in the hot sun. It is not near as common since OPD fill valves have become mandatory. If this should happen to you be thankful your safety device is working properly. Your cylinder will vent excess propane and not explode.

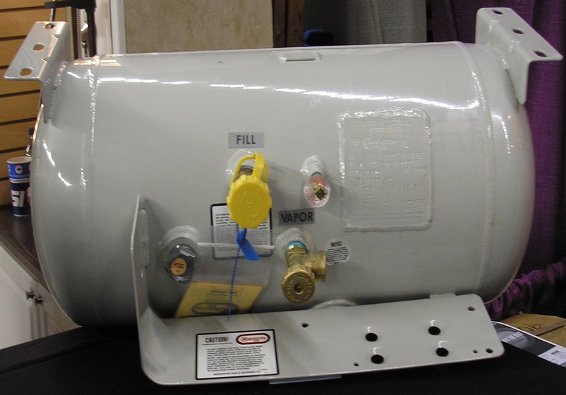

This is a propane tank generally found on motorhomes.

MOTORIZED PROPANE SYSTEMS: Today’s motorized coaches generally have a propane container referred to as a propane tank. This tank is hung from the underneath of the RV. Since 1983 stop fill devices have been required on these tanks. This stop fill device is much like an OPD.

The pressure relief on these containers is set to relieve at 312.5PSI. There are no re-certification requirements for this type of container. The data plate for these containers is attached during manufacturing. Among other markings is the water capacity in pounds.

Different states have different regulations concerning how propane containers are licensed, tagged, etc. Check with your dealer for detailed information. One of the concerns many consumers have is the fact that their propane compartment does not have a lock on the access door. This is correct as the RVIA code specifically requires they be readily accessible.

PURGING: Lack of purging is a very common problem with propane systems. Purging is a procedure to remove atmospheric pressure from the container. All new containers (cylinders and tanks) must be purged. Lack of purging can cause many propane system inefficiencies and safety issues. The list is too long for this article. I have repaired many propane system concerns with purging. Purging is also required anytime a container is open to the atmosphere. This means if the container is ever completely out of propane and the service valve is opened atmospheric pressure has been introduced into the container and it must be properly purged. Purging should only be done by trained qualified personnel using the proper equipment.

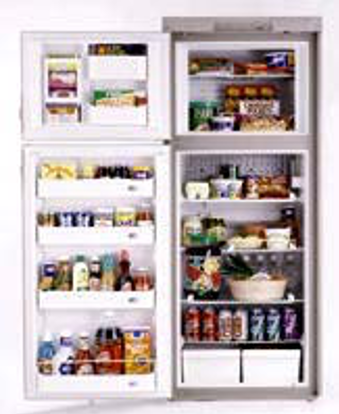

A very common question is “How long will my propane last?”. Simple math will answer this question. Propane has a little over 91,000BTUs (British Thermal Units) per gallon. 91,500 to be closer. To make it simple use 90,000BTUs per gallon. A British Thermal Unit is the amount of heat needed to raise one pound of water one degree at sea level. All appliances will have a tag indicating their BTU use. This figure is BTUs per hour. Divide the number of BTUs per hour into 90,000 and this will tell you how many hours the burner will burn. For example, if you have a 45,000BTU heater, one gallon of propane will run the burner two hours. This is not how long the heater can be on but how long the burner can burn. The number of BTUs per hour commonly used in different RV appliances is:

Furnace…………12 to 45,000 BTUs per hour

Water Heater..8,800 to 12,000 BTUs per hour

Oven Burner……………7,500 BTUs per hour

Range Top…….5,500 to 9,100 BTUs per hour

Refrigerator…..1,000 to 2,100 BTUs per hour

Improper pressure or a changed orifice size can change these ratings. Check your individual appliance for exact figures.

This article is not intended to qualify anyone to work on a propane system. It is simply written to help you become familiar with your propane system. Propane when improperly handled can be very dangerous and should always be treated with the utmost respect. If there is ever a concern about a propane system, a qualified technician should check it out as soon as possible. As I mentioned earlier a yearly safety check is highly recommended. This comes from the RVIA textbooks and is in most RV owner manuals.

Thank you for reading this article.

Gary Motley

Master Certified RV Technician

Member RVDA Learning Center Faculty