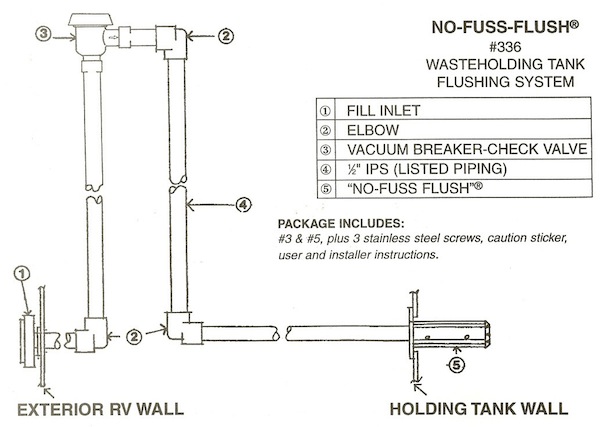

INSTALLER INSTRUCTIONS FOR FACTORY INSTALLATION OF NO FUSS FLUSH @ WASTE HOLDING TANK FLUSHING SYSTEM PART #336

1. Connect sewer hose.

2. Open dump valve; let tank empty.

3. Attach garden hose* to water inlet labeled “Sewer Valve Must be Open When Using This Inlet”. With faucet at full pressure, flush for about 2 minutes or until water runs clear from the discharge hose.

4. Disconnect the garden hose from the faucet and lay on the ground to allow water to drain from the system before detaching from the water inlet.

DO NOT ALTER THIS SYSTEM IN ANY WAY, SUCH AS BY ADDING CHECK VALVES, ETC.

Some DO’S and DONTs for Using The No-Fuss Waste holding Tank Flushing System:

DON’T USE the same hose to fill your potable (fresh) water tank that is used for the No-Fuss.

DO USE the same procedures used at most campground dump stations.

CAUTION

Dump valve must be open any time there is a hose (water supply) connected to this system.

DO NOT LEAVE ANY HOSE (WATER SUPPLY) connected to this system when not in use.

1. Drill I” hole on side or end of the waste holding tank, no more than 2″ from the top near the center.

2. Insert No-Fuss Flush@ in a hole in the “top” position as stamped on flusher and drill 1/8″ lead holes in the tank.

3. Apply clear silicone sealer (do not substitute) completely covering inside of flange (about 3/6″ thick). Fasten with #8 – 1/2″ stainless steel screws supplied. Let silicone cure, following manufacturers’ instructions on the tube, before testing.

4. Install vacuum breaker-check valve a minimum of 6″ above the highest flood level rim of any fixture connected to the waste holding tank (see drawing). Both valves are directional.

DO NOT connect any other backflow preventers (other than enclosed) to this system. Do not use a water inlet with a check valve.

5. Test Flusher system for leaks with a minimum pressure of 40 PSI.

6. Attach enclosed Caution sticker on or near the water inlet to this system.

NOTE: If it is necessary to add any parts to this system, the parts shall be the equivalent of and installed in accordance with IAPMO TSC 27.