It’s time to get acquainted with the Aqua-Hot® system. Hydronic heat means to heat with liquid. Operating similar to a thermos, the Aqua-Hot system holds water, heats it with liquid and keeps it hot for hours. This innovative heating method combines a water heater and furnace into one element, making it easier than ever to tackle the harsh weather conditions of winter camping, or merely take the chill off an early summer morning. The Aqua-Hot system is capable of handling all the coach’s heating needs out of one box, including bay heating.

The core of the Aqua-Hot system is a sixteen-gallon heat tank, which contains a solution of antifreeze. An internal coil wrapped around the tank heats the domestic water. This tank is thermostatically maintained at approximately 200 degrees Fahrenheit. The Aqua-Hot system is equipped with a mixer valve to prevent excessively hot water from flowing through the faucets.

Maintaining the temperature of the solution can be achieved by two separate heat sources — the diesel burner or the electric heating element. When initially running the system, the diesel burner will heat in 10-20 minutes. On start-up, the electric heating element takes about two hours to heat.

Due to its efficiency, the diesel burner is the main heating source of the Aqua-Hot system. A thermostatic switch, set to cycle on and off according to an internal thermostat, controls the diesel burner. The amount of diesel used by the Aqua-Hot system is one to three gallons in a twenty-four hour period. However, a properly operating system will not continuously burn for that long.

A factory-set internal thermostat controls the electric heating element. Electrical power is about one-tenth of the heating capability of the diesel burner and can be used in moderate temperatures when there is a low demand for domestic hot water. Both the diesel burner and the electric heating element can be used at the same time for automatic convenience.

In addition to the diesel burner and electric heating element, a third feature provides engine preheating as a supplemental heating source to reduce the operating hours of the diesel burner. While the vehicle is being driven, the engine’s heated coolant automatically passes through an engine preheat loop to transfer heat into the Aqua-Hot heat tank.

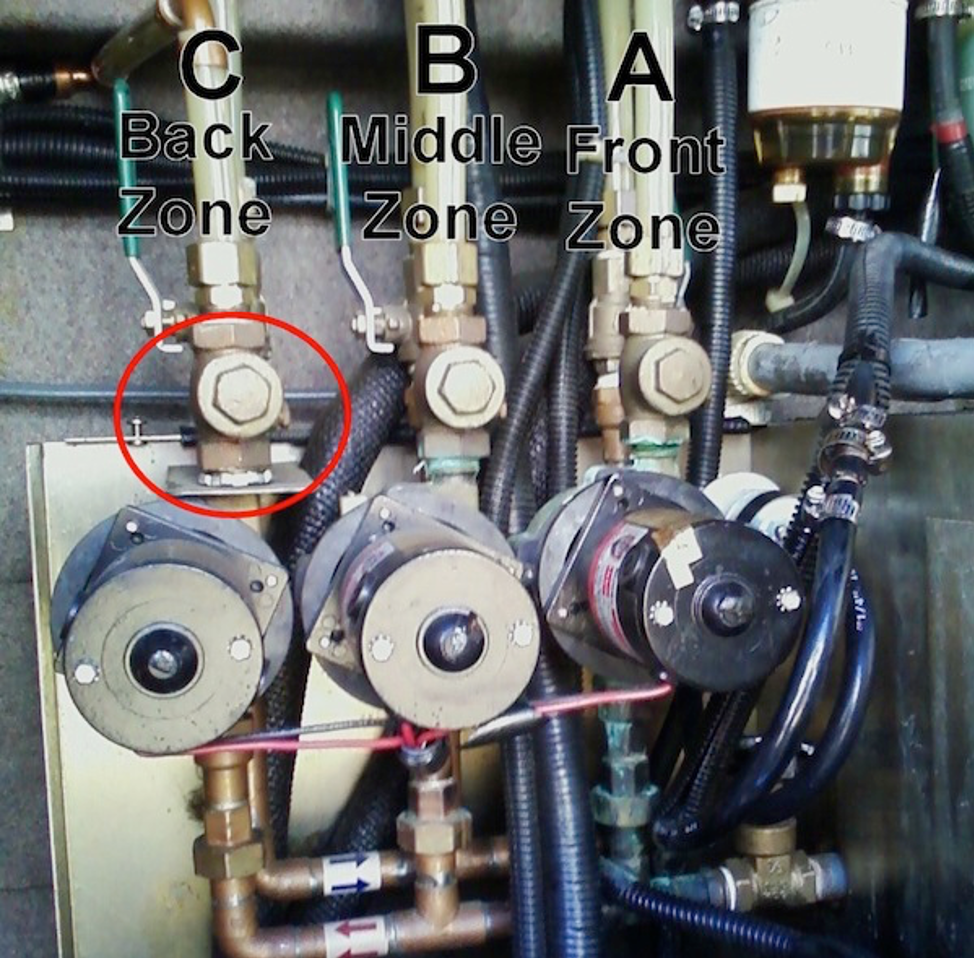

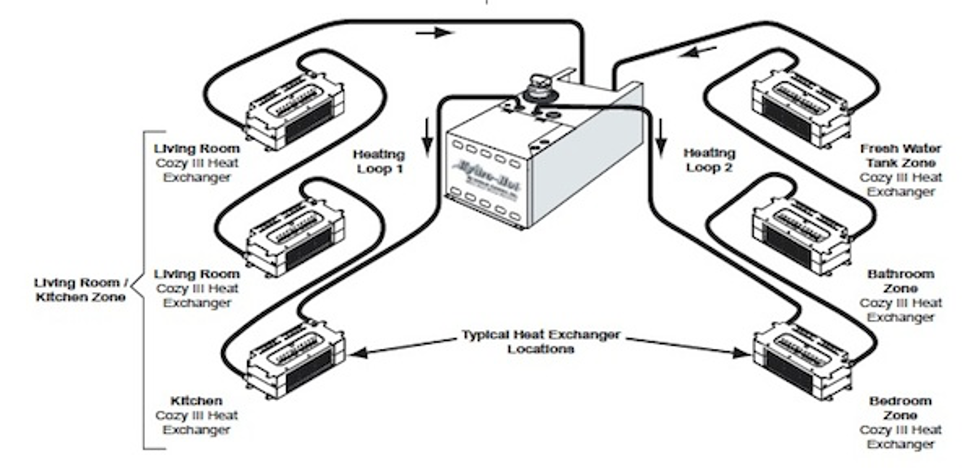

Once the heat tank is up to normal operating temperature, the heated solution of water and antifreeze passes through separate interior heating zones. A series of plastic piping connected within the coach makes up a zone. Each zone is regulated by a thermistor located within the wall thermostats. The middle zone has a separate wall thermistor. It is by this method that the Aqua-Hot system puts controlled heat inside the coach.

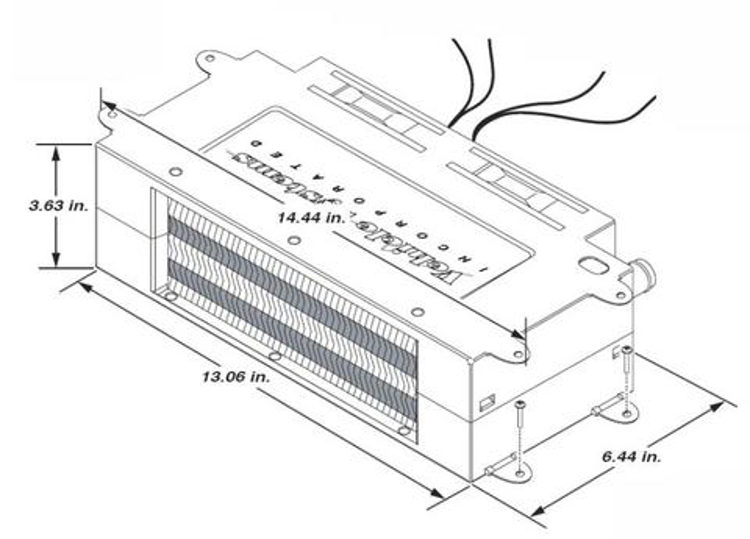

When a wall thermostat calls for heat, the chosen zone circulation pumps and the heat exchanger fans are activated.

The heat exchanger fans operate on 12-Volts DC.

Individual zones can be designated for heat to eliminate hot air from a furnace blasting throughout the entire coach. Heat introduced by the Aqua-Hot system will not dry out the air. Why? Because it does not “superheat” and remove any moisture content the air may have.

The Aqua-Hot system heats fresh domestic hot water automatically. Whenever a hot tap is activated, water is pulled from the coach’s domestic water storage tank and sent to the selected faucet. Since the internal coil surrounds the heat tank, the Aqua-Hot system is continuously heating domestic water on demand. The bay thermostat is set between 45 and 50 degrees Fahrenheit to prevent freezing of the domestic water system located within the coach’s bay area.

Engine coolant can be preheated in cold weather by activating the Engine Preheat switch located on the dash panel. This will propel the Engine Preheat circulation pump to move the engine’s coolant through the Aqua-Hot’s engine preheat loop and warm the engine for easy starting. In colder temperatures, the engine preheat feature should run for a couple of hours or more. This pump can be left overnight if it would be beneficial to do so. The Aqua-Hot system will not overheat the engine. However, the Engine Preheat switch should be off when engine preheating is not necessary. When driving the coach, the preheat circulating pump must be off.

Monthly maintenance consists of visually checking the coolant levels in the expansion tank. The 67/33 solution of water and antifreeze should stay at an appropriate level. This inspection should only be performed when the Aqua-Hot system is heated. Adding a solution to a cold tank will result in overflow as the Aqua-Hot heats up. Operating the diesel burner or electric heating element without the water and antifreeze solution will cause serious damage to the heater.

The Aqua-Hot system is factory calibrated to operate in elevations up to 7,500 feet above sea level. When traveling in higher elevations, it would be wise to contact the manufacturer to discuss any necessary adaptations. Exhaust from the Aqua-Hot system is highly heated. Do not run the system when parked on dry, grassy areas. Never run the system while parked within an enclosed building.

Annual maintenance should consist of a complete tune-up of the diesel burner. The fuel nozzle and filter should be replaced annually. Connections to the fuel line need to be inspected and tightened, if necessary. The combustion chamber can be gently scrubbed with a wire brush. There is a flame sensor (photocell) which monitors the flame of the diesel burner. During annual maintenance, the photocell should be cleaned with a rag to remove any carbon deposits that may have built up. Service personnel should clean and inspect all components for wear and tear.

Turn the Aqua-Hot system off when refueling the vehicle. Prior to cleaning or servicing the system, all power supplies must be disconnected. For preventative maintenance, the Aqua-Hot system should be operated monthly on the diesel burner for at least 10-15 minutes, unless the unit has been winterized. Keep in mind that running the system requires 12-Volts DC.

Different qualities of water can cause scaling problems and create less flow. Have the mixing valve inspected and cleaned once a year. The copper tubing of the Aqua-Hot system is designed for freshwater and winterizing solution. Periodic flushing with chlorine bleach, or other concentrated chlorine-bearing chemicals, can cause failure to the domestic water loop if not completely rinsed and allowed to remain inside of the piping for extended periods of time.

Winterizing the Aqua-Hot system will prevent damage to the domestic hot water loop. This copper tubing must be completely drained of water prior to storing the heater in freezing temperatures. To winterize the Aqua-Hot system, the domestic water storage tank must be fully drained and the demand water pump’s suction line must be disconnected. Using a piece of hose, one end of the hose is attached to the suction side of the demand water pump and the other end of the hose is placed into two gallons of RV antifreeze. Each interior and exterior faucet should be opened and closed, one at a time, until only antifreeze is present. The hose is then removed and the demand pump’s suction line is reconnected. All power supplies are then disconnected.

To flush out the antifreeze and prepare the system for use, the freshwater tank is filled, the demand water pump is turned on and all faucets, interior, and exterior are turned on, one at a time, until clear water is present.

If the diesel burner fails to operate, try the following troubleshooting tips. First, check to ensure that the burner’s indicator light is glowing. If not, turn the burner control switch off and then on again to reactivate. If the light still fails to come on, the diesel burner has malfunctioned, or the bulb is burned out.

Listen to the motor (located under the Aqua-Hot service cover) to determine if it is running. Determine if any air is exiting the Aqua-Hot exhaust pipe by placing a hand roughly six inches from the pipe. If the motor can’t be heard running, or hot air is felt from the exhaust pipe, inspect for blown fuses, loose wire connections or loose plug connectors.

Now that you know the Aqua-Hot system, you can use it to obtain virtually unlimited hot water, controlled heating and preheating during any season of the year. by Technical Publications

Hydronic HeatingOperation and Maintenance Tips by Mark Quasius – 2/06/06

The AH heater in Foretravel installations has two or three fan coils in the saloon, one fan coil in the bathroom, one in the bedroom and two in the utility compartment of the basement.

The fan coils are supplied hot coolant by circulating pumps located in the heater. One pump supplies hot coolant to the saloon fan coils that are plumbed in series. Another pump supplies hot coolant to the bathroom and basement fan coils that are also plumbed in series. One pump supplies hot coolant to the bedroom fan coil. A fourth pump will circulate the Diesel Engine coolant through a tubing coil in the hot coolant tank to preheat the engine before you start it in really cold weather.

The overflow tank allows the coolant to heat up and expand out of the heater into the overflow tank as the temp of the coolant tank rises. The overflow tank level will rise as the heater heats up and fall as the heater cools. So the overflow tank level does not stay at the same level during heater operation.

If the tank level stays the same during operation, check or change the radiator cap and check overflow tube for brittleness and cracking rendering it no longer airtight. If brittle, pull off of barb, cut off one inch and reattach. Both ends need to secure with a clamp, constant tension clamp being the best choice.

You can be assured the fluid level in the system is good when the overflow tank level varies during operation.

A faulty overflow hose will cause the overflow tank to stay at the same level. This does not mean there is no coolant in the heater. But it does mean any expelled or lost coolant is not being replaced by the coolant in the overflow tank and the heater is probably not full of coolant to the neck of the radiator cap.

No coolant in the overflow tank needs looking at with the radiator cap and overflow hose being the most likely suspects. Leaks in the coolant plumbing at the pumps or fan coils will lower the coolant in the heater and cause the coolant in the overflow tank to replace the lost coolant till the overflow tank is out of coolant. Those leaks are fairly easy for the owner to notice. by Rudy Legett 1995 U320