by Gary Bouland

Isuzu 3LD1 Engine on Powertech 10K Generator

As most know I have been having issues with a PT10. Genny is in a 97 U295 owned by an old friend. His health is deteriorating and in addition, he is caring for his wife after many strokes and does not foresee that he will be able to use the coach again. In an effort to help him out I have been trying to get the coach in condition to sell. In addition to setting up for at least 1 and ½ years he also had a lightning strike on the property. The genny would not start and I found that due to bad fuel and disuse the injector pumps had locked up.

I removed the injector pumps and had them rebuilt by a local Diesel injector service company.

When reinstalled I could start the genny but I could not shut it down.

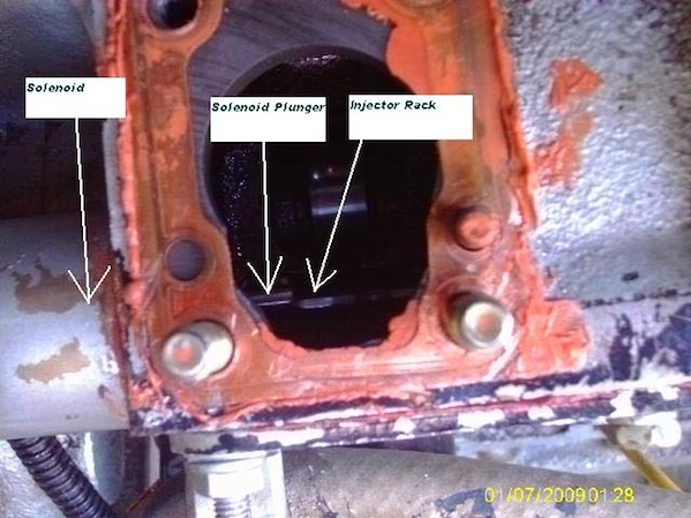

These pumps are activated by a rack attached to the governor’s end of the engine.

The plunger on the solenoid retracts on the engine start to allow the rack to open fuel flow. On shut down, the plunger extends and closes off the flow of fuel. The solenoid plunger would not line up with the rack and the engine would not shut down except by depressing the rack manually with solenoid removed, or moving the lever at the governor.

I was reluctant to mess with this rack and my first opinion was that the rack was hardened steel and could not be bent.

However, after consulting with various experts including several on the forum I discovered that it could be bent. I was told that the probable cause of the rack/plunger mismatch was repeated attempts to start the engine with the injectors frozen. I did not think that the plunger on the solenoid was that strong but I have been proved wrong. After I bent and aligned the rack the plunger would activate the rack and the engine started and ran.

Here is a picture of the pumps.

The pin extending from the injector is what is moved by the rack and it has two positions.

The center position in ON or fuel flow is allowed, the far left or far right is off or no fuel flow.

A couple of warnings……

1. A genny that is not used for long periods can gum up due to diesel fuel deterioration; also water in the fuel will corrode the injector pumps surfaces. Causing the injector pump to freeze up.

SO……. RUN YOUR GENERATOR OFTEN…. The small amount of fuel used is good insurance against injector problems.

2. A fuel stabilizer (STABIL) or the like should be used in the fuel tank if the genny will sit for long periods. (I was told by Powertech that these can set for as long as five years with no problem.) OK, I’ll take their word for it.

3. The copper gaskets under the injector pumps are not gaskets; they are SHIMS and MUST be replaced in the same position as when removed. There should be no reason after factory assembly to shim a pump. Be careful when removing these pumps the shims are tender.

4. Be careful when installing the pumps, under no circumstances should pressure be applied INWARD on the pin that projects from the pump. If the pressure is applied the barrel inside will be displaced and will jam the rack and gear in the pump. Except for the complete lack of knowledge about the operation of this engine, this was not too difficult except for the research and phone calls that it took to get information.