This test is only used for cylinder creep out problems. This test will help to determine if the problem is a leaky cylinder extend solenoid valve or a piston leak in a room cylinder. It is first important to determine if the room is an “A” style room (cylinder extend, room extend) or an “8” style room (cylinder extend, room retract). If the room is an “A” style room, this test is for a room creeping out the problem. If the room is a “B” style room, this test is for a room creeping in the problem. Refer to the “Instruction Sheet-Room Style Identification” on the reverse side of this sheet to determine what style room you are dealing with.

1. Put the room in the proper position, “A” style room fully retracted or “8” style room fully extended.

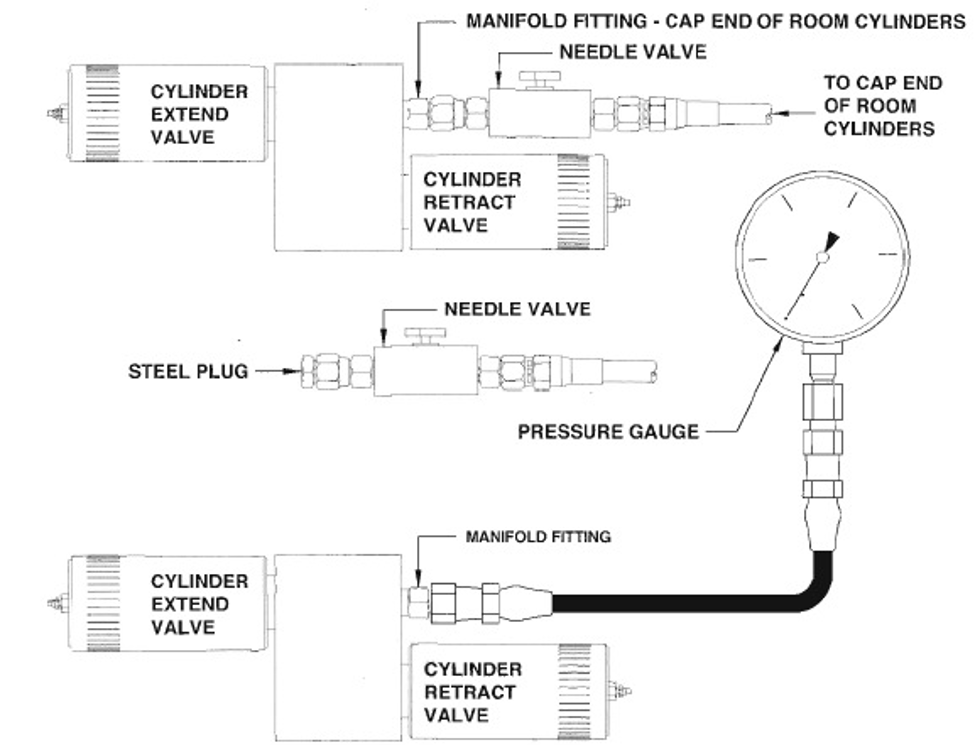

2. Install the needle valve assembly between the manifold fitting and the hose for the cap end of the room cylinder(s) as shown. Make sure the needle valve is open.

3. While holding the room control switch to retract for an “A” style room or extend for an “8” style room, completely close the needle valve. Have the room control switch released when the valve is closed.

4. Immediately remove the needle valve assembly from the manifold fitting. Use the steel plug supplied with the kit to plug the needle valve fitting. DO NOT remove the hose from the needle valve.

5. Attach the pressure gauge to the manifold fitting.

Important: Steps 4 and 5 need to be done as rapidly as possible after the room control switch is released and the pump shuts off.

6. Leave the system in this position for several hours or as long as it takes to complete the test. If the pressure gauge shows an increase in pressure (500+ psi) the cylinder extend valve is leaking. If the room creeps (“A” style out or “8” style in), the leak is in a room cylinder. It is important to note that a leaky room manifold check valve can allow a room to “loosen” or seem to creep a very slight amount. If this happens to be sure to relay this information to HWH Technical Service when you contact them. If the room does not creep and the pressure gauge shows no increase in pressure, reconnect the needle valve to the manifold fitting, cycle the room several times and repeat the test. If the second test shows no definite problem, contact HWH technical service before continuing. Important: You should contact HWH technical service with the test results before ordering parts or completing the repair.