Haldex Air Dryer Filter Replacement instructions on a Freightliner

Bendix Air Dryer Q and A Video

Well… I don’t know how it got away from me, but I’ve not thought to check/change the desiccant cartridge and coalescing filter on the air dryer for some time and had a hell of a time getting the coach home recently. (That’s a story unto itself, but I’ll spare the details.) The bottom line is that when I removed the old desiccant cartridge, it looked like a large container of talcum powder had been poured into every port, inlet, and crevice, and then hosed down with a healthy spray of water. IT WAS A MESS!

I had some problems changing out the relief valve from Desiccant Kit # DQ6026, but other than that, things went better than I would have expected for the first time.

But after getting it all put back together, I’m getting a constant air leak from the purge valve on the very bottom of the dryer. After looking at the troubleshooting guide in the other blog post, the problem appears to be a damaged purge valve seal, or perhaps just foreign particles on that seal. At any rate, I’ guess I’m going to have to take that Purge Assembly apart, and probably replace.

It can be changed on the couch, remove the black plastic cover on the bottom then remove the retaining clip and the purge valve will come out.

I already had the plastic cover off. I was having a heck of a time getting the snap ring off. It had evidently rotated into a position that would not let me use the snap-wring pliers. I got frustrated enough that I ended up disconnecting the air hoses and removing the air dryer.

I went ahead and removed the old Purge Valve and clean the chamber since the sun was shining this afternoon.

I used patience, a can of aerosol degreaser, and paper towels. I was reluctant to spray the degreaser into the purge valve housing, as I was concerned that it would drain further into the air dryer. So I tore off small pieces of paper towels, saturated them with the degreaser, and used a small screwdriver to work the paper towels into the edges and corners of the housing.

It was slow and tedious, for sure, but I feel pretty good about getting all that grunge cleaned out.

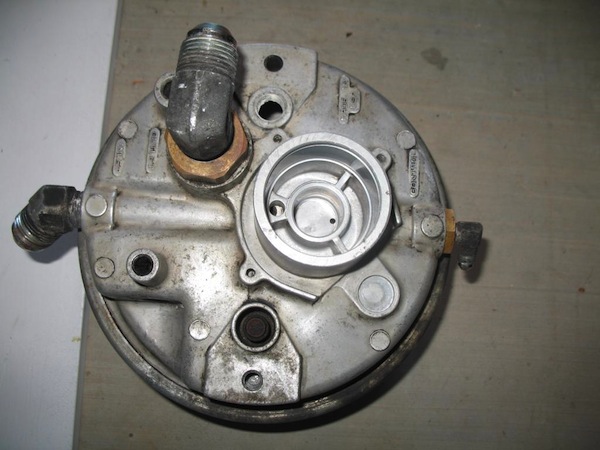

Air Dryer (bottom) before w purge valve

Air Dryer (bottom) w-o purge valve

Air Dryer (bottom) with purge chamber cleaned

I was able to pick up the DQ6020 (Major Repair Kit) from NAPA this AM and will try to further disassemble the air dryer when it warms up.

DQ6020

HOLY COW, was it a mess! No wonder it didn’t seat and was leaking air.

Posting some before/after cleaning in case anyone who has not torn into their air dryer might be curious as to what it’s NOT supposed to look like.

Coalescing Filter

Desiccant Canister

Purge Valve by Russell 1999 U320 40′ 12/21/10

My AD9 has at least 8 nuts at the base, and 2 wide bands around the canister that have to be loosened. In our coach, the dryer is tucked away in the far passenger-side corner of the engine compartment behind the hydraulic reservoir for the power steering pump. The only way to get clear access to the dryer is to drop it out of the bottom of the compartment. Not an easy task in the ’92 U-280.

My impression has been that the outer canister just protects the other components (heater, desiccant, purge valve, etc.), so I don’t know why it would hurt to open it up, but again, others on this forum are more qualified to answer this. Don Hay 1992 U280

Turns out I have a Haldex Pure Air Plus in my 1999 U-270.

It took a turn for the worse a few weeks ago and started sounding like a gun going off in rapid-fire. It was a little disconcerting. Figured that reliable air was a good thing to have on a coach with Air suspension and brakes. So we called Haldex and they felt that the unit needed to be rebuilt. They were very helpful and suggested that if we were to do the job, the rebuild it ourselves was the way to go. If we were having a shop do it, they said buy a new one and have them do a remove and replace. It would probably work out to about the same total cost than buying the rebuild kit and paying the labor for a mechanic to rebuild it.

So with my trusty friend Bob Cramer we took on the job yesterday. A little intimidating since everything was old, rusty, big, and covered with grease. Plus if we didn’t get it done right, ‘t have air, and therefore probably wouldn’t be able to move.

Here is what we (Bob Cramer and I) did yesterday in about 5.5 hours

(BTW, last week I cleaned the bottom of the coach with Solvent sprayed with on with compressed air. I bought a sprayer and a solvent. Menards- sprayer was $11 and the solvent (mineral oil basically) was $38 for 5 gallons. I used about two quarts. Then I put “Mouse Milk” on everything that needed to come loose. Mouse Milk is a great penetrating oil used in the aircraft industry (Chief Aircraft Parts always has it in stock – get some) in preparation for this job.

With some trepidation, off we went, chocked front and rear wheels, and then used air suspension to pick up the rear of coach – then blocked it up with wood 4 x 4’s to keep it up for sure.

On my coach, there were four 9/16 head bolts holding the unit to the coach with 7 different air lines connected to the unit. Mark the lines in some fashion – colored tape, etc., take a picture, draw a diagram so it will go back together easier. We didn’t and I ended up reversing the main air lines at re-install. It didn’t hurt anything but wasted 45 minutes figuring it out and switching.

BTW – The rebuild kit lists for $55 or so. I bought it online for $44 and $5 shipping. (New Dryer is $299 and a rebuild I saw online was $229). This, of course, does not include the expensive filters.

Found system drain in front of drivers sides rear tire and drain system.

I fought the little sucker out of the coach (clearly the hardest part of the job – rust, rust, rust) This took about 3 hours and some ingenuity, hammers, a big pipe, the 1 1/14 wrench, and three pipe wrenches. The two large air lines were the biggest issue they were very rusted, especially the input side as you might imagine since it was the “wet” compressed

I carefully followed the instructions on the rebuild kit and rebuilt the unit changed out the parts in three different areas of the dryer (really well written and easy to follow instructions. If you get to the rebuilt part, you will be able to successfully get this job done. It is more of a light disassembly and reassembly with a few new parts and o-rings.

Going back in was the easy part. (Except if you didn’t make a sketch or take pictures so you would know which direction the fittings faced, etc.) Next time we will take pictures and a diagram. It is pretty hard to screw up, it just took a little more time to get the fittings facing the right direction, and all the lines back where they belong.

Once we did that and started the coach, did the “operational check” per the instructions, which is let the pressure build and when it reaches the upper limit, and fairly loud burst of air comes out followed by about 30 seconds of air hissing.

All good and the coach is back in service.

Hard stuff in this job.

Dealing with rusty lines – needed the ingenuity to get them off. Some while still on the coach, others after we got it partially out.The two big ones required 1 1/4 inch wrench. If you have that and a few pipe wrenches, a piece of pipe to increase leverage, and typical sockets, pliers, screwdrivers, vise, the bench you have the tools you need. You also could use a set of snap ring pliers. Not everyone has those, but we ended up using a pair of needle nose

Tight quarters to get work done. Grease and dirt everywhere and everything you touch. Figuring out how to block up coach – used air suspension – (check valve holds up airbags even when no pressure on the system, and I actually fit well under the coach – but wouldn’t want that

Not sure “Diesel mechanic” title is for everyone – but thanks to my friend Bob Cramer we “got her done” Tim Fiedler 1999 U270 7/07

A couple of important things we can comment on based on our (Steve’s) experience working on the Haldex air dryer on our 2003 U320.

To change the filter, you will need to dump the air completely out of the coach. No air brakes, no airbags, no air anything. Make sure you are level, CHOCKED, and have completely dumped the air out of the airbags first. Steve dumped the air using the front “air dump” switch, then opened all the valves around the coach.

The filter itself comes off just like an oil filter.

There was also a coalescing filter that fits down the middle after you unscrew the main filter. It pulls straight out for replacement.

Steve says it will take longer to fully dump the air than it will to replace the two filters. Ours also came as a kit with instructions. We got it from FT parts, who had the best price at the time we were shopping. Michelle & Steve 5/16/2009

The filter spin on and coalescing filters cannot be salvaged. You would not want to take the chance of getting junk in the brake lines. Also while rebuilding my unit (1995) I found that some parts had been upgraded. Since I now know that mine is completely clean and working correctly, next time I will just replace the spin-off filter kit and not have to completely remove the unit and fight a huge fitting with a large pipe wrench to replace the internal parts. About a day after I did mine I found that the entire unit can be purchased rebuilt for about 50.00 more than the three kits cost, so for the less technically determined individuals, I believe the already rebuilt unit is the way to go. Since the unit has to come off to replace the pop-off valve anyway. But if you only need the filter, then the filter kit is the way to go. But I would imagine that anyone with a vintage of 2000 or older really should rebuild the entire unit, not just replace a filter. Each kit came with the necessary instructions and all grease and seals were included. Greg Jones 1995 U280 5/17/2009

Cummins South called and told me I could bypass the dryer as see if the air would build up to test it. I couldn’t do that, but I was able to disconnect the two large hoses. Started the coach back up and I was getting good air ‘chuffing’ out the compressor outlet hose. I’m now much more satisfied that the air dryer is indeed the culprit.

FYI, the Cummins guy said the most they almost ever have to do on a compressor is replace ahead.

Spoke to Derek at MOT he advised me to also get the lower repair kit Dave Head 95 U320C SE 40 1/4/10

At a past Foretravel Mid-South Rally in Amarillo, TX; one coach had a similar problem. The air dryer had not been changed and thru time and aging the internals blew up, plugging the system; it was a mess with desiccant powder distributed throughout the RV’s air system.

James Triana was attending the meeting to give his technical presentation; he changed it to the air dryer system (Haldex) and shared with everyone the system is overlooked and should be changed on an annual basis; as part of the repair/replacement kit is a pop-off valve, the gaskets, the desiccant, etc. As I recall both John, Jack, and James were working to pull airlines and trying to purge desiccant powder from them – it was a mess.

You will need ground down (thinned) open-end or boxed end (best) wrench to remove the unit; I cannot find my notes from the meeting, but John Hughes was the person who changed unit out which was on a ‘95 coach. I remember this since I had a ’95 coach at that time.

You will need a thinned down wrench. I do remember that much from when John Hughes showed it to me. The wrench size was removed but I think it was 9/16; Triana can confirm.

John D. McKee ’04 U320 – 42’