by Jim McNeece 2003 U320 40′ 12/15/13

Faced with having to replace some or all of the HWH leveling solenoid valves due to desiccant powder contamination, I have been searching for an alternative to purchasing new solenoids at $109 each.

HWH will rebuild a solenoid for a maximum charge of $76.50 each plus shipping. Still, more than I want to spend since I believe any problem I expect to find can be solved by simply replacing the solenoid plunger (I expect desiccant powder has accumulated on the plunger seats, adversely affecting their sealing ability).

Others have reported leaking solenoid plunger seats resulting from various causes. One person, can’t remember who reported that he used a lathe to successfully resurface the plunger seats. A guy, Richard, over on the Newell Guru’s forum removes the seat material and replaces it with RTV of the correct hardness (Shore A Durometer reading of about 72, he reports).

I asked HWH if they would sell just the plunger, but they said no. So, off to the Internet.

After looking at hundreds of pictures, I decided that a Skinner replacement plunger V5-207-N available from these nice folks Inventories in Stock by Oemsurplus911.com would work. I bought 6 for $17 each (no returns) for initial testing.

Solenoid Plunger Comparison

A comparison between a new HWH plunger (I took apart a new solenoid I had purchased this summer while at HWH) and the replacement is shown in Photo 1. They are virtually identical except for the seat diameter. The HWH seat is 0.3″ while the replacement’s seat is 0.2″. This feature limits the replacement to use on the small orifice (3/32″) solenoids (there are two large orifices, 5/32″, solenoids used for tag dump). I can live with that.

The dimensions (inches) are:

| HWH | Replacement | |

| Stem Diameter | 0.441 | 0.442 |

| Length: | 1.170 | 1.185 |

| Flange Diameter | 0.540 | 0.610 |

| Seat Diameter | 0.30 | 0.20 |

The seat material is black on the replacement plunger, but seems about the same hardness as the HWH.

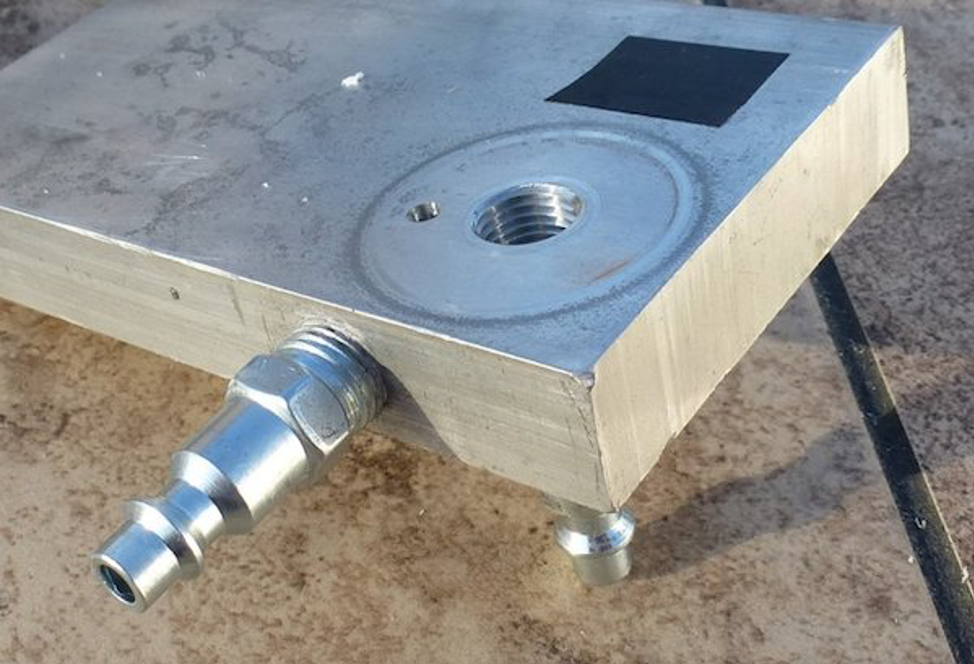

I built a test jig that simulates an HWH manifold (see Photo 2). I tested one of the replacement plungers in a new HWH solenoid up to 150 psi with no leaks. I, also, switched the solenoid open and closed a number of times, still with no leaks.

I have no idea if these replacements have the durability (or lack thereof) of the HWH plungers, but I am willing to give them a try. I ordered more so I can replace all but the two large orifice solenoids.

Use this information at your own risk. I am not endorsing the use of the replacements. I’m just willing to be a guinea pig.